Monday, April 30, 2012

Bush Knives

Two machetes or "bush knives":

The top one has a 15 inch blade and was given to me by my dad, who had it with its scabbard since I was a kid. It is made by Collins & Co., as is the longer one below which I found at a yard sale. The "Legitimus" trademark is stamped on both machete blades:

Collins & Co. was located in Collinsville/Canton, Connecticut. Starting in 1826, they made various edge tools, as well as hammers and wrenches. During the U.S. Civil War, they were one of the smaller producers of swords used during this conflict. In the 1920's, shoddy imitations offered by competitors under their name led them to develop and use their Legitimus crown and arm logo. In 1940, when British suppliers had their hands full meeting British Army needs, Collins & Co. were awarded the contract to produce "bush knives" for the Canadian Army, which they designated as model number 1250. These were intended to be carried on tanks and vehicles in offensive actions in Europe. I can't find anything about what the longer model 1131 (1181?) was intended for.

The machete below also turned up at another yard sale:

Beautiful tooled leather scabbard stamped "M Mateco, Habana, Enna Y Concha." Unfortunately, some previous and moronic owner must have attempted to pry something with the blade, since the end is snapped off. The blade is stamped "Corona" and W.K. "Acero Diamante" means "diamond steel" in Spanish. Others ones with this name offered on the web have their place of manufacture attributed to El Salvador.

In fact, the crossed swords and crown "Corona" logo above indicates that the blade was made by Weyersberg, Kirschbaum & Cie of Solingen, Germany.

The steel is interesting on it. Ribbed, almost as if it were beaten by a hammer on an anvil, which it may have been.

Sunday, April 29, 2012

Japanese wrenches

Hozan (HKC) is a Japanese tool company based in Osaka which began in 1951. On their website they state:

“Our products are specially designed to meet with professional tool standard. Manufactured with human-logic in mind that will give a sense of joy and pride to the users."

The reverse side of the same wrench looks like this:

Now, instead of Hozan: and "HKC", it says "NTK". If you google this, it appears that this company made wrenches for Toyota and Nissan cars. However, the only Japanese company I can find by this name is NTK out of Nagoya, which is a ceramics specialist and part of the NGK (Nihon Gaishi Kaisha) spark plug empire. It seems unlikely that they would be making wrenches. However, on their website they say, "At NTK Technologies, we do not make the products that you see everyday. However, our innovation helps to advance many of the technologies and products that improve people's lives." And people say the Chinese are inscrutable!

Aigo is based in Sanjyo City, Niigata Prefecture. It was founded by Gosaburo Aida as the Aida Iron Factory in 1928 to produce farm implements. In 1940, it was converted to military production, but returned to farm machinery in 1945. In 1960, the company changed its name to Aigo Kogyo Co. Ltd. The company website includes:

Words from the President: "Our company encourages each employee to be creative, having confidence and pride in themselves, and to have a fighting spirit, so as to offer products with originality. Our company hopes to continue to be 'a good company worth relying upon'."

Special Mention: "We produced our first handtools 40 years ago and now our AIGO brand handtools are highly valued as the top-ranking products by our end users. We have been contributing greatly to society by producing metal products useful to various industries, with a high degree of technology, cultivated over many years."

Maybe it's just cant, but nevertheless you don't see these kinds of sentiments on American tool manufacturers' sites.

Saturday, April 28, 2012

Vanished Makes: CVA

On the American-made Speedway electric drill (featured in a previous blog posting) I discovered that the chuck was made in England by a company called CVA. Speedway was at that time a division of the Thor Power Tool Company, and it would seem from other online comments that Thor used this make of chuck on other models of their electric drills as well.

CVA were manufacturers of automatic gear cutters, gear hobbers, automatic lathes, dieing presses and milling and die-sinking machines. C.V.A. began in 1917 as C. A. Vandervell & Co Ltd. (C.A.V.) to produce war materiel including munitions. Between the wars a foundry and heat-treatment shop were added, and in 1934 the name was changed to C.V.A. Jigs Moulds & Tools Ltd. In 1945, CVA acquired the factory space of The Old Diamond Works, which had been built in 1918 to give war disabled jobs polishing diamonds. (There's a certain irony to that.) There they made fractional horse power electric motors, drill chucks and lathe chucks. Post World War II, business was so good the company had no fewer than 73 apprentices working for it. They continued to offer a toolroom lathe, an expensive machine whose cost (between £700 and £1000) was the same as a nice house in most UK cities. They appear to have ceased making drill chucks in the 50's or mid-60's at the latest. They also diversified into domestic appliances, on the premise that the post-war market would be flooded with machine tools. To that end, they produced the CVA Columbine vacuum cleaner and the CVA electric iron. However, Hoover soon got back into this business in a big way, sweeping the market so to speak. CVA had been a supplier for the Milwaukee-based Kearney & Trecker company, and in 1966 they were acquired by the American firm. Kearney & Trecker were innovators in the area of computer-controlled machines (including involvement in the US space program) and many employees did their apprenticeships at CVA. (As an interesting aside, skins for the Avro Arrow were made on Kearney & Trecker machines.) Factories were closed and operations consolidated during the 1970's and, now under the F.M.T. name, the firm wound down during the 1990's.

|

| Canadian Machinery, 1916 |

Tona A.S. Pecky, Czechoslovakia

This is a 13 mm/17 mm wrench I picked up.

It was made by Tona A.S. Pecky, which in Czech means the Tona company out of the city of Pecky, which is 45 kilometers east of Prague in central Bohemia. The company was founded in 1892 as an iron foundry, and then as a manufacturer of agricultural and industrial tools. It entered the professional tool market in the 1950's.

Below, two other Tona wrenches in my possession:

Note the company logo below, I suspect referring to Czechoslovakia:

In 1992, controlling interest in the company was bought by Stanley (now Stanley-Black & Decker). That American tool company is trying very hard to own everything.

One of my vices is vises, miniature

Friday, April 27, 2012

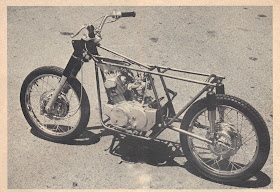

Van Tech frames

In the late seventies I picked this bike up with the intention of going roadracing. The 4 speed Suzuki B100P based engine was hopelessly out of date by then despite the grafting of a modified X6 cylinder to the 120cc bottom end. I embarked on an updating plan using a CanAm 175 engine but life overwhelmed the project and the bike was sold to a friend. He installed an X6 engine and made it road legal. After awhile, in forgotten circumstances, I got it back and it has remained around in bits ever since. At some point I realised that although the bike was homemade it had been based on an aftermarket frame kit from Van Tech.

Several magazines used these kits for feature projects.

160 Honda from Oct, Nov 1967 issues of Cycle Guide.

Good looking bike.

The ad below was in various motorcycle magazines from 1967 and 68 and was probably how I learned the origin of my frame. The impression at the time was these kits made excellent handling bikes and were much lighter than stock. Easily made adapter plates meant you could use almost any engine. The TT seat looks like a Bates item. The aluminum tank looks unique to Van Tech.

The Honda S90 from February 1968 Cycle magazine

160 Honda from Oct, Nov 1967 issues of Cycle Guide.

Good looking bike.

Hodaka belonging to Paul Stannard

Vantech was Bill Van Tichelt who started in 1963 by producing a manifold for the then popular McCulloch kart engine. This combination found itself in a motorcycle he built and probably looked much like the one below. The bike was very successful in its class and led to VanTech selling bikes with various engines. Ad below from 1965. This led to the development of the frame kits for the various small Japanese singles under the Grant Van Tech and Roehr Van Tech names. The last mention I can find is the one-off frame for Gordon Jennings' "Son of Secret Weapon" 350 Bridgestone project.

More Vantech info here.

More Vantech info here.

|

| Seen at a local swap meet. |

Double BSA

Seemed like a good idea at the time I guess, what with the the new Honda Four and Triumph Trident having just been released. After all, they were only 750cc.

Hawker Hart

Thursday, April 26, 2012

CB400F header

Cycle Magazine March 1972. Say, those pipes look familiar! When the CB400F arrived in two years later with its iconic 4-1 header, could it be that Honda stylists had seen this ad for aftermarket CB750 pipes before?

1925. H.M.Walter in his 'Jappic'

H.M.Walter in his 'Jappic' of 1925, good for 68.79 mph using a 350 cc JAP single cylinder engine.

http://en.wikipedia.org/wiki/Jappic

Wednesday, April 25, 2012

Dymaxion

|

| James F. Fales, Everett G. Sheets, Gregg J. Mervich & John F. Dinan. Manufacturing: A Basic Text. Second Edition. Glencoe/McGraw-Hill, 1986. |

This three-wheeler was designed by F. Buckminster Fuller to travel at 120 mph and get 40 miles per gallon. As a young engineer, he convinced Nannie Biddle (a famous aviatrix and contemporary of Amelia Earhart) to finance his experiment. With the help of 27 skilled workers, they built a prototype that had an 85-hp V-8, front wheel drive, but steered by the single rear wheel (so it could be turned around on the spot). Driver and passenger seats had rear-view periscopes. The car was 19 feet long, planned to seat four but had room for eleven. Made primarily of aluminum, it weighted only 2300 pounds. Fuller had a gas driving the prototype around New York City, creating traffic jams from all of the attention it garnered. According to the manufacturing text referenced above (and contrary to what Wikipedia reports) it call came to an end when one of the test drivers was taking an interested buyer back to the airport, and rose to the challenge of a politician who came along side and suggested a race. The two cars reached speeds of 70 mph before the politician lost control and crashed into the Dymaxion, killing himself and seriously injuring the passenger. The politician's role was initially hushed up, and the press labelled the Dymaxion a killer car. That ended the car's brief career.

Tuesday, April 24, 2012

Stafford Diesel

|

| More Stafford liners in an earlier post |

.jpg)

.jpg)

.jpg)