Saturday, December 31, 2016

Early Hydroplanes

A major advance in the development of Glen Curtis' seaplanes was his invention of the stepped pontoon that allowed his aircraft to break free of the waters surface, leading to the first successful liftoff from water on January of 1911. However there was nothing new about the idea of a stepped hull, the earliest documented evidence seems to be the 1970s ideas and experimentations of a Reverend C.M. Ramus of Sussex England who produced the sketches below. His ideas were dismissed as impossible and ludicrous at the time but as the development of compact and lightweight gasoline engines changed speedboat design, the advantages

The concepts were all out there, experiments and experience were proving them practical but it took the creative mind of Glen Curtiss to adapt them to aircraft.

|

| Images from D.W. Fostle, Speedboat, Mystic Seaport Museum 1988 |

Friday, December 30, 2016

Christmas, Kennedy Airport, 1967

Thursday, December 29, 2016

Ride the CPR to Quebec City!

In an attempt to promote their hotel business, the Canadian Pacific ran advertising programs for destinations all over Canada- even in the off season.

Renault Étoile Filante

|

| Gianni Marin, The Motor Car, London House and Maxwell 1963 |

According to Wikipedia in the mid-nineties Renault restored and drove the car. It is now in the Renault's Historical Cars Collection.

We used to make things in this country. #241: Hussman Refrigerator Company, Brantford, Ontario

The Hussman firm was founded by Harry L. Hussman in 1906 as a butcher's supply company in St. Louis, Missouri. His big break came in 1917, when he patented the first refrigerated meat display case. Made out of wood with a glass front, it was cooled using salt and ice and revolutionized the meat market, allowing customers to view the cuts before purchasing them. In 1948, the company ventured into Canada. In Brantford, Ontario, they bought the Ruddy-Freeborn company, established by some local businessmen to manufacture cabinets for refrigerators. The Brantford factory had originally been established in 1892 as the Ham Brothers, making refrigerators alongside products like woven wire bed springs, screen doors, window screens, kitchen cabinets and beekeeper supplies.

In 1925, it became the Ruddy Manufacturing Company and then, in 1936, Ruddy-Freeborn. Under Hussman's control, the firm turned to producing the company's display cases. In 1981, the parent Hussman Refrigerator Company became the Hussman Corporation. In the late 1990's, the American Hussman company underwent restructuring, consolidating production from five locations down to two American ones in St. Louis and Bridgeton, Missouri. All told, over $50 million was invested in the Missouri facility. Brantford was to be downsized and slated to be closed in the first quarter of 1999 but was not shut down until 2002. (The company's Atlantic Canada branch, which began as Palmer's Refridgeration before being acquired by Hussman in 1981, was unaffected although no manufacturing was carried out there.)

The Hussman closure follows on the heels of many other firms that have pulled out of the Brantford area: Harding Carpets, Trailmobile, Koehring, Ladish, Chicago Rawhide, Gates, Genfast, Raymond, Hussmann, Sternson and many others. It all seems to have begun with the failure of the Massey Combines Corporation in 1988 which put 2500 people out of work. (For pics of the abandoned factory today, visit Abandonned UE.)

In April of 2016, Hussman was bought by Panasonic for $1.5 billion. It remains to be seen if the new Japanese owners will treat the American company in the same way that the former American owners treated their Canadian subsidiary. Hey--it's not personal, it's business.

Tuesday, December 27, 2016

de Havilland Heron

|

| Mid Atlantic Air Museum |

The eight passenger two engine DH.104 Dove was the de Havilland company's replacement for the 30s biplane Dragon Rapide. It was first flown on the 25th September of 1945, only five and a half months after the end of the war. The Dove became a popular choice as a small short-haul airliner and over 500 were built.

|

| Colour mages from Gordon Bain, De Havilland, A Pictorial Tribute, Airlife Publishing, 1992 |

The company saw a market for a larger version and the DH.114 Heron was the result. A direct development of the previous plane, a good number of DH.104 parts were utilized in the design. The fuselage was stretched 9 feet to carry 14 passengers and the wings lengthened to take four engines. The engines used were smaller and the aircraft proved to be underpowered. Despite this it was a popular plane with airlines servicing remote and rough airfields. Production ceased in 1963 but a number of companies did engine conversions that gave the craft a new lease on life and examples remained in service into the 90s. 150 in total were built.

Surplus surgical lamp

This coffin-like box appeared in my Christmas stocking this year, a gift from a dear friend and long time partner in crime...

It seems that during the Cold War part of the government preparation for disaster was the ability to set up temporary field hospitals wherever needed. The date on the box is June 16 1966. This well-packed surgical lamp was part of the warehoused supplies.

Unscrewing eight #10 screws from the lid reveals an extendable 110 volt floor lamp with heavy cast base, an extra bulb and a two prong adapter. Nothing else, not even an instruction manual. There is no indication of where it was made. The company name is Rencraft Products Ltd. of Toronto with only a post office box for an address. I don't see any information on the company on the internet.

The 50 year old cardboard boxes are in perfect condition, better made than any modern product, I can't bring myself to throw them out!

Vanished Tool Makers: Barcalo Manufacturing Company, Buffalo, New York

Below, my small collection of Barcalo "Double Grip" wrenches. I'm assuming they were called this because the inside of the opening is shaped like the side of the hex to better fit the bolt head or nut, rather than just curved as in most open-end wrenches. The designer, J.M. Vallone, was assigned a patent for the design in 1938.

|

| 1941 |

Back in the day, my assortment of wrenches would have been worth almost a dollar! Barcalo also produced wrenches with other distinctive designs:

Below, pliers made by the firm:

In 1890, at the tender age of 20, Edward Joel Barcalo (1870-1963) came to Buffalo, New York, seeking his fortune. He found employment as a book-keeper for the Buffalo Brass and Iron Bedstead Company. A short six years later, he bought the assets of the company to found the Barcalo & Boll Manufacturing Company. (His partner, Charles S. Boll, was a successful Baltimore businessman who owned, among other enterprises, the Boll Brothers Manufacturing Company of Harrisburg, Pennsylvania the largest American producer of mattresses, spring beds and brass and iron bedsteads. Maybe he and Barcalo met at an exhibition of their companies' respective wares? It's possible. While pre-dating Barcalo's ownership of his company by 11 years, a description of an 1885 exhibition states the following:

In any event, Edward Barcalo was both an astute businessman and an innovator, holding patents for a bed spring, canned synthetic snow, and mint-flavoured ice cream. His company originally made a wide range of metal products including beds, cribs and outdoor furniture.

The Boll Brothers Manufacturing Company, with its brass and enameled bedsteads and splendid display of mattresses, was in a reserved seat as far as trade was concerned, and booked many new orders. The old customers, it goes without saying, stuck by it and merely came in and pointed out the duplicates they required.

The Buffalo Brass and Iron Bedstead Company showed a line embracing the cheapest iron as well as the finest brass bedsteads, and the same was received with every evidence of satisfaction by the watchful retail visitor. )

|

| 1897 |

|

| 1908 |

|

| 1909 |

Over the next two decades, the company grew substantially, spreading to 8 buildings.

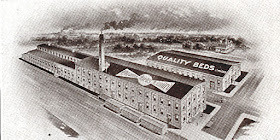

(Barcalo Manufacturing also made beds in Welland, Ontario under the Quality Beds name from 1904 to 1914. The firm occupied the premises of the Cleveland-based Frost Wire Fence Company which had set up shop in Welland in 1898 before relocating to Hamilton which offered a greater tax advantage. At its height, Quality Beds was producing 3000 brass beds a year!)

|

| Welland Public Library |

In 1914 the acquisition of the Charles E. Hall company led to the addition of hand tools as a product line, supplying Curtis-Wright and the burgeoning aviation industry. This was a good business move since the wartime demand for metal ended the American production of iron beds in 1915. During World War I, 90 percent of Curtiss Wright's aviation forgings came from the factory. After the Great War, Barcalo began supplying tools to the Ford Motor Company, and also selling them through the Larkin Company's mail order business. Below, that company's factory, with administration building designed by Frank Lloyd Wright, demolished in 1950:

|

| http://buffaloah.com/h/larkin/admin/photos.html |

(As an aside, I found the following on kunstler.com: "At its height of success a hundred years ago, the Larkin Company provided a stupendous bounty of social support services for its 4,500 employees: a dental office at nominal prices, dedicated rooms at local hospitals, an on-premises branch of the city library, subsidized night school classes, gyms, lounges, sports clubs, a credit union, insurance plans, and more.")

In the early 1940's, Dr. Anton Lorenz entered the picture. Born in Budapest, Hungary, Lorenz (1891-1964) was something of a Renaissance man. Starting off as a history and geography teacher, he then accompanied his opera-singer wife to Germany in 1919 where he worked in the lock industry. He entered the furniture business in 1927 and formed his own company two years later. His specialty was the design of tubular steel furniture. (The steel tube divan with waxed thread covering "LS 22" from 1931 was his most famous design.) When war broke out in 1939 he happened to be on a business trip to Paris. In a clearly wise decision, Lorenz fled Europe to America where he presented his ideas to Barcalo. In 1940, Barcalo bought Lorenz's patent for a "scientifically articulated" motion chair which he had based on adjustable hospital beds and, according to the advertising copy, by studying photographs of people floating in water. Initially, the design was used for wheelchairs for injured World War II vets. In 1941, the first metal and canvas "Just-It" adjustable outdoor reclining chairs went into production and in 1946 the company had produced the first "BarcaLoafer", soon to be re-named the "BarcaLounger."

|

| 1946 |

|

| Life, January 1953 |

It went head-to-head with the older La-Z-Boy, first made in 1927 by Ed Shoemaker and Ed Knabusch of Monroe, Michigan. In the contest between the two brands, the BarcaLounger had the advantage of incorporating a built-in footrest. In 1947, Barcalo merged with Chandler Industries, a maker of upholstered furniture which occupied Barcalo's original factory in Black Rock. By the 1950's the company was employing 550 workers, but Edward Barcalo was over 80 and began to back away from the day-to-day operation of the business. On his death in 1963, the tool division was sold to Crescent Niagara which had already acquired Crescent Tools and Billings & Spencer, and which would add the Bridgeport Hardware Manufacturing Company to its fold the following year. The Barcalo identity and brand name soon disappeared. In 1968, Crescent Niagara itself was absorbed by Cooper Industries, at the beginning of the trend towards giant corporate ownership of formerly independent tool companies.

As for the parent company, two years later it was sold to Mohasco Industries, which relocated manufacturing to Rocky Mount, North Carolina. In 1989, it became Barcalounger Inc. In 2005, the company was acquired by Hancock Park Capital which, one year later, bought American of Martinsville, Virginia from La-Z-Boy and merged the two companies. In 2009, the North Carolina factory was closed and production was consolidated in Martinsville. One year later, the Martinsville plant was closed without warning and the company sought bankruptcy protection. The firm was bought by HPC3 Furniture Holdings, a Hancock affiliate, which moved production to China. According to a company executive, in 2015, production was returned to the U.S. at an undisclosed location in North Carolina. Barcalounger itself is headquartered out of Morristown, Tennessee.

As an interesting aside, the Barcalo company claims to have been the first U.S. company to institute a coffee break. In the early 20th century, most employees came to work by bicycle or trolley, starting work at 8 a.m. and working until lunch break at 12:30. This seemed a long stretch so, in 1902, a 10 o'clock break for coffee was agreed upon, as well as a mid-afternoon break. In 1912, the company also started the very first in-house hot lunch program for its employees. All very progressive! And the original factory building still exists: http://www.preservationready.org/Buildings/255LouisianaStreet

Reading about the employee benefits pioneered by companies like Barcalo and Larkin, you can't help but wonder how modern, presumably more enlightened businesses and corporations have gone in the other direction, driving down wages, eliminating benefits, and removing the kinds of job supports and security that were possible a century ago in a less affluent age. Progress is fine...

Reading about the employee benefits pioneered by companies like Barcalo and Larkin, you can't help but wonder how modern, presumably more enlightened businesses and corporations have gone in the other direction, driving down wages, eliminating benefits, and removing the kinds of job supports and security that were possible a century ago in a less affluent age. Progress is fine...

Monday, December 26, 2016

Sunday, December 25, 2016

Megantic Clothes pins

It appears the Megantic Wood Products company is still around, now making birch veneer for door skins but the clothes pin production is long gone...

PT boat by Higgins

|

| D.W. Fostle, Speedboat, Mystic Seaport Museum 1988 |

Short Bros. Silver Streak

The most revolutionary British aircraft of 1920 was the all-metal monocoque-fuselage Silver Streak built by Short Aviation. Neither it nor the Short Springbok that resulted from the design could be considered particularly successful, and it took till the late thirties for this method of construction to become common.